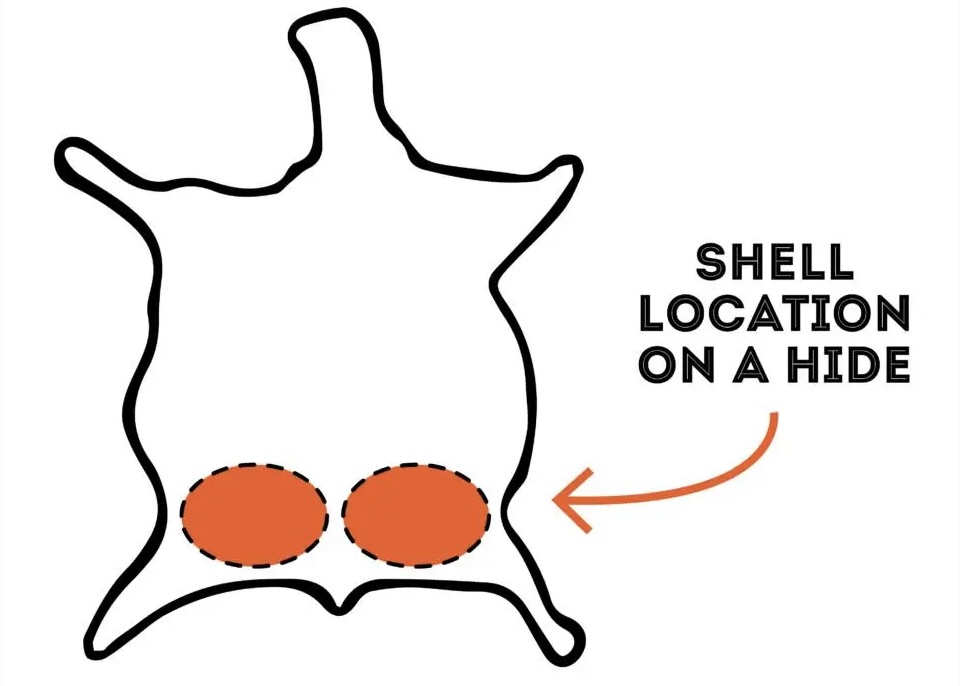

In brief, the production process looks like this. First, the parts that are used for the cordovan are cut out of the hide; they are located in the croup area, at the back of the horse. Then the wool is removed, after which the pieces of hide are put into a solution of tannins. At Horween, it includes chestnut bark, Quebracho tree bark, and resins. There they are moved regularly, which allows them to better absorb the necessary elements. After a month the skins are taken out of the solution and the top layer is removed to leave the membrane mentioned earlier – in fact, it is this membrane that will become cordovan. Then the parts of skins are immersed for a month in another solution – more concentrated. After this time, the membranes are removed from it and dyed by hand with aniline dyes. Then, in most cases, they are polished with glass cylinders to achieve a characteristic lustre, glossiness and visually deep colouring. Finally, the membranes are left to “rest” for several months – an important step that should not be neglected. Cordovan can be dyed in a limited range of colours. One of the best known and most popular is red-brown; two other common colours are burgundy-brown (Burgundy) and black. You can also find cordovan in dark brown, red-brown, blue and even green colours; the last two are still very rare.